160x Filetype XLSX File size 2.22 MB Source: prod-drupal-files.storage.googleapis.com

Sheet 1: Guidance

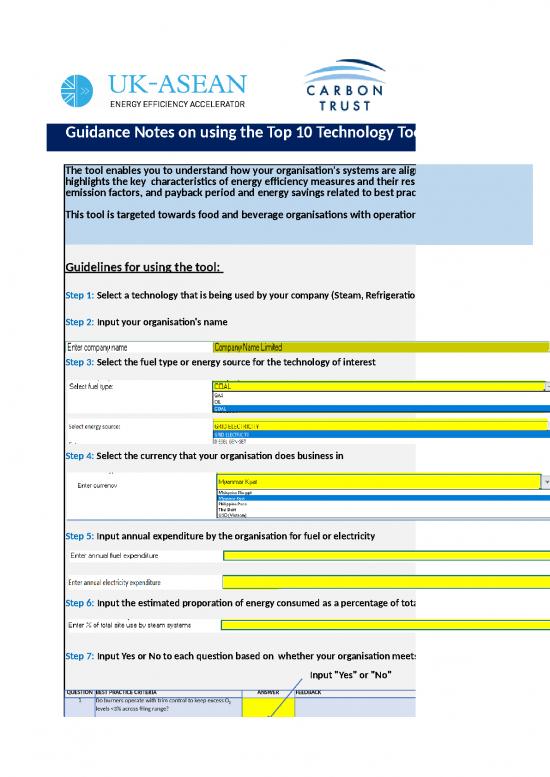

| Guidance Notes on using the Top 10 Technology Tool |

|||||||

| The tool enables you to understand how your organisation's systems are aligned with best practice for commonly used technologies in the food and beverage sector. In addition, the tool highlights the key characteristics of energy efficiency measures and their respective energy and cost savings estimates. The tool uses data on country specific fuel costs by type of energy source, emission factors, and payback period and energy savings related to best practice energy efficiency measures. This tool is targeted towards food and beverage organisations with operations in Malaysia, Myanmar, Philippines, Thailand and Vietnam. |

|||||||

| Guidelines for using the tool: | |||||||

| Step 1: Select a technology that is being used by your company (Steam, Refrigeration, Compressed Air, Motors & Drives, Cooking, Distillation) | |||||||

| Step 2: Input your organisation's name | |||||||

| Step 3: Select the fuel type or energy source for the technology of interest | |||||||

| Step 4: Select the currency that your organisation does business in | |||||||

| Step 5: Input annual expenditure by the organisation for fuel or electricity | |||||||

| Step 6: Input the estimated proporation of energy consumed as a percentage of total energy consumption by the site for the selected technology | |||||||

| Step 7: Input Yes or No to each question based on whether your organisation meets the best practice criteria stated. | |||||||

| Example of tool outputs: | |||||||

| After you input your answers, the tool will automatically generate feedback on the energy, cost and emissions savings based on your organisation's alignment with best practice. | |||||||

| If you are unable to indicate “YES” to all questions, it is likely that the efficiency of your system could be improved, saving you money and reducing your carbon emissions. | |||||||

| The authors, the Carbon Trust, its agents, contractors and sub-contractors give no warranty and make no representation as to the tool's accuracy and accept no liability for any errors or omissions. All trademarks, service marks and logos in this publication, and copyright in it, are the property of the Carbon Trust (or its licensors). Nothing in this tool shall be construed as granting any licence or right to use or reproduce any of the trademarks, services marks, logos, copyright or any proprietary information in any way without the Carbon Trust’s prior written permission. The Carbon Trust enforces infringements of its intellectual property rights to the full extent permitted by law. The Carbon Trust is a company limited by guarantee and registered in England and Wales under company number 4190230 with its registered office at 4th Floor Dorset House, Stamford Street, London SE1 9NT. Published in the UK: 2020. © The Carbon Trust 2020. All rights reserved. |

|||||||

| EE Guidance for Steam System Opportunities |

||||||||

| PROCESS TYPE: STEAM SYSTEMS | ||||||||

| DATA ENTRY INSTRUCTIONS | ||||||||

| For instant feedback on how your steam system is performing against best practice standards, simply enter your company name, select fuel type, select your currency of operation, enter your annual fuel expenditure, and enter the % of total energy used by the system. Then simply answer "YES" or "NO" to each question. | ||||||||

| Please input into all the yellow fields. | ||||||||

| Enter company name | ||||||||

| Select fuel type: | ||||||||

| Enter currency | ||||||||

| Enter annual fuel expenditure | ||||||||

| Enter % of total site use by steam systems | ||||||||

| QUESTION | BEST PRACTICE CRITERIA | ANSWER | FEEDBACK | NEXT STEPS | ||||

| 1 | Do burners operate with trim control to keep excess O2 levels <3% across firing range? | |||||||

| 2 | Is the boiler water level controlled by a modulating feedwater control system? | |||||||

| 3 | Are boilers fitted with automatic TDS controls? | |||||||

| 4 | Are flue gas discharge temperatures <200°C? | |||||||

| 5 | Are boilers operated at their design pressure (as opposed to a lesser required system pressure)? | |||||||

| 6 | Is the flash steam from TDS blowdown being recovered to the feedwater tank via a deaerator head? | |||||||

| 7 | Is energy recovered from residual blowdown effluent? | |||||||

| 8 | Is the feedwater tank maintained at a temperature >85°C? | |||||||

| 9 | Is at least 85% of condensate being recovered and returned to the feedwater tank? | |||||||

| 10 | Are all sections of steam and condensate pipework, valves, vessels and fittings effectively insulated? | |||||||

| The authors, the Carbon Trust, its agents, contractors and sub-contractors give no warranty and make no representation as to the tool's accuracy and accept no liability for any errors or omissions. All trademarks, service marks and logos in this publication, and copyright in it, are the property of the Carbon Trust (or its licensors). Nothing in this tool shall be construed as granting any licence or right to use or reproduce any of the trademarks, services marks, logos, copyright or any proprietary information in any way without the Carbon Trust’s prior written permission. The Carbon Trust enforces infringements of its intellectual property rights to the full extent permitted by law. The Carbon Trust is a company limited by guarantee and registered in England and Wales under company number 4190230 with its registered office at 4th Floor Dorset House, Stamford Street, London SE1 9NT. Published in the UK: 2020. © The Carbon Trust 2020. All rights reserved. |

||||||||

| EE Guidance for Refrigeration System Opportunities | |||||||

| SYSTEM TYPE: REFRIGERATION | |||||||

| DATA ENTRY INSTRUCTIONS | |||||||

| For instant feedback on how your refrigeration system is performing against best practice standards, simply enter your company name, select fuel type, select your currency of operation, enter your annual fuel expenditure, and enter the % of total energy used by the system. Then simply answer "YES" or "NO" to each question. | |||||||

| Please input into all the yellow fields. | |||||||

| Enter company name | |||||||

| Select energy source | |||||||

| Enter currency | |||||||

| Enter % of total site use by refrigeration systems | |||||||

| QUESTION | BEST PRACTICE CRITERIA | ANSWER | FEEDBACK | NEXT STEPS | |||

| 1 | Are the correct set point temperatures being used based on system duty/requirements? | ||||||

| 2 | Has every effort been made to minimise the ingress of warm air to the refrigerated spaces? | ||||||

| 3 | Has the heat load within the refrigerated space been minimised? | ||||||

| 4 | Are the condensers kept as cool as possible and regularly cleaned? | ||||||

| 5 | Are the evaporator surfaces free from ice? | ||||||

| 6 | Is the pipe insulation regularly checked for staining or ice? | ||||||

| 7 | Does the refrigeration system utilise Liquid Pressure Amplification (LPA)? | ||||||

| 8 | Does the system utilise electronic expansion valves with feedback control? | ||||||

| 9 | Does the system utilise heat recovery? | ||||||

| 10 | Do your current chillers use HFCs or HFOs as refrigerants? | ||||||

| 11 | Are you operating a 15+ year old chiller? | ||||||

| The authors, the Carbon Trust, its agents, contractors and sub-contractors give no warranty and make no representation as to the tool's accuracy and accept no liability for any errors or omissions. All trademarks, service marks and logos in this publication, and copyright in it, are the property of the Carbon Trust (or its licensors). Nothing in this tool shall be construed as granting any licence or right to use or reproduce any of the trademarks, services marks, logos, copyright or any proprietary information in any way without the Carbon Trust’s prior written permission. The Carbon Trust enforces infringements of its intellectual property rights to the full extent permitted by law. The Carbon Trust is a company limited by guarantee and registered in England and Wales under company number 4190230 with its registered office at 4th Floor Dorset House, Stamford Street, London SE1 9NT. Published in the UK: 2020. © The Carbon Trust 2020. All rights reserved. |

|||||||

no reviews yet

Please Login to review.