258x Filetype XLSX File size 0.07 MB Source: www.twi-global.com

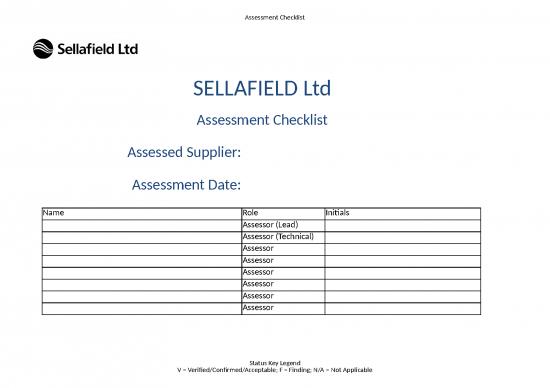

Sheet 1: Assessment Checklist

| SELLAFIELD Ltd | |||||

| Assessment Checklist | |||||

| Assessed Supplier: | |||||

| Assessment Date: | |||||

| Name | Role | Initials | |||

| Assessor (Lead) | |||||

| Assessor (Technical) | |||||

| Assessor | |||||

| Assessor | |||||

| Assessor | |||||

| Assessor | |||||

| Assessor | |||||

| Assessor | |||||

| Areas for review are as follows | Nominated Team | ||||

| 1. Nuclear Safety Culture | |||||

| 2. Quality Management System | |||||

| 3. Resource Management (Key Personnel) | |||||

| 4. Procurement (Including Specific purchase order review) | |||||

| 5. Subcontractor Selection and Control | |||||

| 6. Contract Review | |||||

| 7. Quality Plans | |||||

| 8. Assurance | |||||

| 9. Certificate of Conformity | |||||

| 10. Records | |||||

| 11. Internal Audit and Programme | |||||

| 12. Document Control | |||||

| 13. Welding Arrangements | |||||

| 14. NDT Arrangements | |||||

| 15. Testing Arrangements | |||||

| 16. Painting and Coating | |||||

| 17. Foreign Material Exclusion | |||||

| 18. Counterfeit, Fraudulent and Suspect Items | |||||

| 19. Calibration | |||||

| 20. CE Marking | |||||

| 21. Non Conformance | |||||

| 22. Traceability | |||||

| 23. Goods Inward | |||||

| 24. Goods Release | |||||

| 25. Packaging and Transport | |||||

| 26. Fabrication Drawings | |||||

| 27. Facilities | |||||

| Clause | Description | Standard | Finding / Verified | Evidence | |

| 1 | Nuclear Safety Culture | SLM 4.06.02 | |||

| 1.1 | The Contractor shall establish and promote an effective Nuclear Safety Culture aligned to the traits and attributes defined above within its own organisation and that of its supply chain by: | SLM 4.06.02 - 1.1 | |||

| a. Ensuring a common understanding of the key aspects of Nuclear Safety within the organisation. | |||||

| b. Providing the means by which the contractor is able to develop a Nuclear Safety Culture. | |||||

| c. Reinforcing a learning and questioning attitude at all levels of the organisation about Nuclear Safety. | |||||

| Verify the requirements a-c are being met | |||||

| There are 8 internationally accepted principles of a strong Nuclear Safety Culture: | |||||

| · Everyone is personally responsible for nuclear safety | |||||

| · Leaders demonstrate commitment to safety. | |||||

| · Trust permeates the organisation. | |||||

| · Decision-making reflects safety first. | |||||

| · Nuclear technology is recognised as special and unique | |||||

| · A questioning attitude is cultivated. | |||||

| · Organisational learning is embraced. | |||||

| · Nuclear safety undergoes constant examination | |||||

| Verify if the Supplier have evidence for the following: | |||||

| Nuclear Safety Toolbox talks | |||||

| Nuclear Safety Dashboard | |||||

| Nuclear Safety Posters | |||||

| Flow-down Nuclear Safety in their Supply Chain. | |||||

| 1.2 | SLM 4.06.02 Issue 3 Clause 1.2 States… | SLM 4.06.02 - 1.2 | |||

| The Contractor shall ensure that all Personnel involved in the provision of work for Sellafield Ltd understand any Nuclear Safety implications of failure of the product or service to meet the specified design intent. | |||||

| Do the personnel involved in the provision of work have an understanding of the impact of the failure of product /service for SL | |||||

| Do they understand what happens if it goes wrong? | |||||

| 1.3 | SLM 4.06.02 Issue 3 Clause 1.4 States… | SLM 4.06.02 - 1.4 | |||

| The Contractor shall ensure that Personnel are aware of the implications of Suspect and Counterfeit products being deployed on the Sellafield site. | |||||

| Can the contractor demonstrate the awareness of suspect counterfeit products within their organisation?01 02 03 | |||||

| 1.4 | SLM 4.06.02 Issue 3 Clause 1.5 States … | SLM 4.06.02 - 1.5 | |||

| Finally, the transition from manufacturing, fabrication, construction, through commissioning to operations needs to be appropriately managed in order to ensure the necessary knowledge is passed over to the requisite personnel. | |||||

| Are all the phases covered for nuclear safety as above. | |||||

| 2 | Quality Management System requirements | ||||

| 2.1 | All Contractors shall maintain a quality management system that is compliant to the latest edition of BS EN ISO 9001 standard or equivalent, and which has been certified by a United Kingdom Accreditation Service(UKAS), accredited Certification body or International accepted equivalent. | SLM 4.06.02 - 2.1 | |||

| Has the ISO 9001:2008 certificate been provided for review? Is it on display with the latest Quality Policy and are personnel aware of it and what it means? | |||||

| Review the last surveillance/ recertification report for required actions and their effective close out. | |||||

| 2.2 | SLM 4.06.02 Issue 3 Clause 2.2 States … | SLM 4.06.02 - 2.2 | |||

| The Contractor shall monitor, review and update its quality management systems as necessary to comply with Good Industry Practice and to ensure continued certification. | |||||

| Has ISO 9001:2008 been maintained, is the QMS up to date? Review last update | |||||

| 2.3 | SLM 4.06.02 Issue 3 Clause 2.3 States … | SLM 4.06.02 - 2.3 | |||

| At contract award the Contractor shall have implemented their quality management system in accordance with the Customer’s requirements. | |||||

| Does the QMS align to SL’s requirements? | |||||

| 2.4 | SLM 4.06.02 Issue 3 Clause 2.4 States… | SLM 4.06.02 - 2.4 | |||

| In the event that the Contractor’s quality management system is made up of a multiple number of certified quality management systems (alliance/ collaborative partnerships), the Contractors” shall make their operational quality management system available to the Customer within 10 working days of contract award for formal audit if requested by the Customer. | |||||

| Can this be demonstrated? | |||||

| 2.5 | SLM 4.06.02 Issue 3 Clause 2.5 States … | SLM 4.06.02 - 2.5 | |||

| The Contractor shall appoint a suitably qualified and experienced Quality Management representative, supported by competent experienced personnel, to ensure effective implementation of the quality management system. | |||||

| Verify SQEP of the appointed quality personnel | |||||

| 2.6 | SLM 4.06.02 Issue 3 Clause 2.13 States … | SLM 4.06.02 - 2.13 | |||

| The Contractor shall have a Business Continuity process in place that identifies potential threats to the organisation and the impacts to business operations those threats, if realised, might cause. The Contractor shall have in place an effective response that safeguards the interests of its key stakeholders, reputation, brand and value-creating activities. | |||||

| Consider, for example: | |||||

| • Adverse Weather (snow/ice, floods) | |||||

| • Fuel Crisis/Loss of utilities | |||||

| • Pandemic (loss of personnel) | |||||

| • Loss of premises (fire, flood etc.) | |||||

| • Loss of Systems (IT/comms/information)/Cyber attack | |||||

| • Loss/disruption to your supply chain | |||||

| • Others applicable to your business | |||||

| Verify there is a business continuity plan in place to cover the scope of the contract. Is there evidence of periodic review and has the process been tested. | |||||

| 2.7 | SLM 4.06.02 Issue 3 Clause 2.14 States… | SLM 4.06.02 - 2.14 | |||

| The Contractor shall have a documented process for Learning from Experience to demonstrate improvement, and be able to show effective implementation. | |||||

| Verify if there is a LFE process within the organisation. | |||||

| Verify information source, for example Opex briefs, project issues and audit findings. | |||||

| 2.8 | SLM 4.06.02 Issue 3 Clause 2.15 States… | SLM 4.06.02 - 2.15 | |||

| In addition to the Contract Quality Requirements, Contractors engaged on Sellafield Ltd projects shall follow SLSP 1.10.315.01, “Quality Standards for SL Projects and Contractors engaged on SL Projects”, and its subsets as stated in the Contract. | |||||

| If the supplier/subcontractor is engaged on a SL project, this shall be demonstrated. | |||||

| 3 | Resource Management | ||||

| 3.1 | SLM 4.06.02 Issue 3 Clause 3.1 States… | SLM 4.06.02 - 3.1 | |||

| The Contractor shall implement an induction course. The Contractor shall ensure that all personnel deployed on the works receive the induction course prior to commencing work on the contract. The induction course shall as a minimum include: | |||||

| · Nuclear Safety | |||||

| · Safety requirements | |||||

| · Security requirements | |||||

| · Overview of the works | |||||

| · Mandatory procedures | |||||

| · Standards and Specifications requirements briefs | |||||

| Verify the contents of the induction course have been covered. Have personnel employed before this course was initiated had their training gaps filled? | |||||

| 3.2 | SLM 4.06.02 Issue 3 Clause 3.2 States… | SLM 4.06.02 - 3.2 | |||

| The Contractor shall determine and provide the appropriate number of SQEPed resources required to deliver the contracted scope of work and agree the levels with the Customer. | |||||

| Verify the levels have been agreed and whether this can be shown to have been complied with, sample key roles such as: | |||||

| QC Inspectors / NDE Examiners | |||||

| Quality Manager | |||||

| Supervision | |||||

| Welders | |||||

| 3.3 | SLM 4.06.02 Issue 3 Clause 3.3 States… | SLM 4.06.02 - 3.3 | |||

| The Contractor shall ensure that all Personnel they assign to undertaking work for the customer are suitably qualified and experienced to deliver the assigned work. There should be a clear auditable trail that demonstrates that the contractor's staff is equally as "SQEP" as licensee staff would be for the same role. | |||||

| Review SQEP of personnel assigned to undertaking work for the customer. | |||||

| 3.4 | SLM 4.06.02 Issue 3 Clause 3.4 States… | SLM 4.06.02 - 3.4 | |||

| The Contractor shall implement and maintain a competency/training register supported by appropriate training and qualification records. The register shall identify: | |||||

| · All personnel engaged on the works | |||||

| · Role Specification | |||||

| · Status of training received for each individual | |||||

| · Experience of each individual | |||||

| · Forward Plan to close out identified competency requirements | |||||

| Review training records to verify compliance. | |||||

| 3.5 | SLM 4.06.02 Issue 3 Clause 3.5 States… | SLM 4.06.02 - 3.5 | |||

| The Contractor shall routinely perform documented reviews of personnel to maintain competency. | |||||

| Verify training reviews are carried out and periodicity is in accordance with contractor’s procedure. | |||||

| 3.6 | SLM 4.06.02 Issue 3 Clause 3.6 States… | SLM 4.06.02 - 3.6 | |||

| The Contractor shall notify the customer of any deficiencies identified with personnel competency that may affect the product or service provided. The Contractor shall take corrective actions to eliminate personnel competency deficiencies. | |||||

| Has this been necessary? How was it resolved | |||||

| 3.7 | SLM 4.06.02 Issue 3 Clause 3.9 States… | SLM 4.06.02 - 3.9 | |||

| The Contractor shall define and implement appropriate arrangements to control any change to its organisational structure or resources which may affect environmental, health and safety, security and quality performance. | |||||

| Verify what arrangements are in place. | |||||

| Establish if NIS have strength in Depth to deliver the project. | |||||

| 3.8 | SLM 4.06.02 Issue 3 Clause 3.10 States … | SLM 4.06.02 - 3.10 | |||

| The Contractor shall notify the Customer formally of any organisational changes that could impact on environmental, health and safety, security and quality performance. | |||||

| Have there been any changes in key personnel in these fields? Evidence of notification? | |||||

| 3.9 | SLM 4.06.02 Issue 3 Clause 3.11 States… | SLM 4.06.02 - 3.11 | |||

| The Contractor shall be able to demonstrate the qualification and independence of Personnel verifying or inspecting work from those performing the work. | |||||

| Verify this requirement | |||||

| 3.10 | SLM 4.06.02 Issue 3 Clause 3.12 States… | SLM 4.06.02 - 3.12 | |||

| All Inspection & Test quality control personnel deployed on the works are suitably experienced and shall be in possession of nationally recognised qualifications | |||||

| Review training records, qualifications and CVs. | |||||

| 3.11 | SLM 4.06.02 Issue 3 Clause 3.13 States … | SLM 4.06.02 - 3.13 | |||

| All testing and inspection practitioners shall be experienced in the application of the technique to the specific material. | |||||

| Review training records, qualifications and CVs. | |||||

| 4 | Procurement | ||||

| 4.1 | SLM 4.06.02 Issue 3 Clause 4.1 States… | SLM 4.06.02 - 4.1 | |||

| The Contractor shall implement a graded approach in accordance to the Sellafield Ltd SLP 4.06.05 for the procurement of products and services to mitigate the risk of failure. For additional detail please see above “A Graded Approach to Procurement”. | |||||

| Verify how the requirement is met | |||||

| 4.2 | SLM 4.06.02 Issue 3 Clause 4.2 States… | SLM 4.06.02 - 4.2 | |||

| The Contractor shall ensure that purchasing information accurately specifies the product or service to be purchased. | |||||

| Review purchase orders to verify this | |||||

| 4.3 | SLM 4.06.02 Issue 3 Clause 4.3 States… | SLM 4.06.02 - 4.3 | |||

| The Contractor shall ensure that the requirements of the contract, the Sellafield Ltd Contract Quality Requirements, the appropriate standards, and necessary requirements to deliver the products and services specified are flowed to all tiers of the Contractor’s supply chain, and that understanding is tested. | |||||

| Verify this requirement is met | |||||

| 4.4 | SLM 4.06.02 Issue 3 Clause 4.4 States… | SLM 4.06.02 - 4.4 | |||

| The Contractor shall ensure the purchasing information accurately specifies the requirements for acceptance of products and services, to include as applicable: | |||||

| · Reference to this CQR | |||||

| · Quality Grade | |||||

| · Specification(s) | |||||

| · Drawing(s) | |||||

| · Material Type | |||||

| · Quantity | |||||

| · Certification requirements | |||||

| · Inspection requirements, at vendor, on delivery or both | |||||

| · Functional testing requirements, at vendor, on delivery or both | |||||

| · Any special requirements such as packing, extra testing etc | |||||

| · Requirements for procured services | |||||

| Verify sample purchase orders comply with this. | |||||

| 5 | Sub-contractor Selection and Control | ||||

| 5.1 | SLM 4.06.02 Issue 3 Clause 4.7 States… | SLM 4.06.02 - 4.7 | |||

| The Contractor shall have a process for subcontractor selection through assessment and analysis of their competencies, facilities and equipment to ensure that they have the capability to conform to the contract requirements, delivering products and service safely, to schedule, of the correct quality and to the agreed cost. | |||||

| Review contractor’s process and select examples of assessment, for compliance. | |||||

| 5.2 | SLM 4.06.02 Issue 3 Clause 4.9 States… | SLM 4.06.02 - 4.9 | |||

| The Contractor shall assess the subcontractor’s capability to plan and meet the required capacities beyond existing or new contracts. | |||||

| Verify compliance | |||||

| 5.3 | SLM 4.06.02 Issue 3 Clause 4.10 States… | SLM 4.06.02 - 4.10 | |||

| The Contractor shall ensure that any weaknesses identified during tender assessment are managed post contract award. | |||||

| Were any issues identified, if so verify the effectiveness of the additional conditions required. | |||||

| 5.4 | SLM 4.06.02 Issue 3 Clause 6.3 States… | SLM 4.06.02 - 6.3 | |||

| The Contractor shall implement a process for ongoing verification and monitoring of their Subcontractors to ensure that they are delivering products and services safely, to schedule, to the specified requirements and to the agreed cost. | |||||

| Verify the Contractors process achieves the requirements | |||||

| 5.5 | SLM 4.06.02 Issue 3 Clause 6.4 States… | SLM 4.06.02 - 6.4 | |||

| The SL Tier 2 Contractor shall produce a diagram that shows the totality (inclusive of materials, components, sub-assemblies, assemblies and plant items) of the supply chain delivering the contracted scope of work. The diagram shall take the form of an organisation chart. Colour coding in accordance with SLF 1.10.315.13 to identify the type and level of assurance to be applied by the Contractor to each subcontract. | |||||

| The diagram shall specifically include: | |||||

| · Organisational hierarchy between contracting parties | |||||

| · Names of contracting parties | |||||

| · Quality assurance arrangements (audit, surveillance, inspection and test) that shall be applied to each subcontractor. | |||||

| · The Contractor shall submit the diagram to the Customer with the tender for acceptance. The diagram shall be maintained throughout the lifetime of the contract. | |||||

| Verify that the diagram has been created and complies | |||||

| 5.6 | SLM 4.06.02 Issue 3 Clause 6.5 States… | SLM 4.06.02 - 6.5 | |||

| The Contractor supplying products or services directly to Sellafield Ltd shall, in accordance with the Contract, provide for acceptance a schedule of intended Subcontractors, using Sellafield Ltd form CFMT 121 – “Main Contractors identification and proposed control of Sub Contractors and Suppliers.” The Contractor shall only Subcontract work in accordance with the agreed schedule submitted with the tender or in accordance with agreed changes following submission of a revised schedule. | |||||

| Verify compliance and review approval | |||||

| 5.7 | SLM 4.06.02 Issue 3 Clause 7.2 States… | SLM 4.06.02 - 7.2 | |||

| The Contractor shall document and establish Subcontractor assurance and oversight arrangements to ensure compliance with the Sellafield Ltd specifications, standards and Contract Quality Requirements. These arrangements shall be tailored to mitigate risk to Nuclear Safety. | |||||

| Verify compliance | |||||

| 6 | Contract Review | ||||

| 6.1 | SLM 4.06.02 Issue 3 Clause 4.12 States… | SLM 4.06.02 - 4.12 | |||

| The Contractor shall ensure that all contract requirements for the scope of work are reviewed, agreed and understood prior to the commencement of work both within their own organisation and their supply chain. | |||||

| Verify the records of the review meeting. | |||||

| How was understanding promoted and verified? | |||||

| 6.2 | SLM 4.06.02 Issue 3 Clause 4.13 States… | SLM 4.06.02 - 4.13 | |||

| The Contractor shall confirm the understanding of the works information package/ Purchase Orders via opening up meetings held with their subcontractors and explain each clause of the specification to ensure full understanding of the requirements. | |||||

| Where the contract includes the following elements the review shall as a minimum include the following:- | |||||

| · Project/Contract Management | |||||

| · Commercial | |||||

| · Health and Safety | |||||

| · Quality (including Nuclear Safety and Specification Awareness Briefs) | |||||

| · Project Controls (planning, programme and costs) | |||||

| · Risk | |||||

| · Engineering | |||||

| · Construction | |||||

| · Commissioning | |||||

| · Operations and Maintenance | |||||

| · Provision of product samples (when requested) | |||||

| · Life Time Records (LTRs) | |||||

| Verify how the Contractor has ensured that subcontractors fully understand the requirements | |||||

| 6.3 | SLM 4.06.02 Issue 3 Clause 4.14 States… | SLM 4.06.02 - 4.14 | |||

| The Contractor shall establish a process for ongoing contract review throughout the life of the contract. | |||||

| Verify records confirm reviews take place and that any actions raised have been completed | |||||

| 6.4 | SLM 4.06.02 Issue 3 Clause 6.1 States… | SLM 4.06.02 - 6.1 | |||

| The Contractor shall ensure that the full extent of their supply chain has a clear understanding of the Sellafield Ltd contract Technical and Quality specified requirements. | |||||

| Verify how the contractor has ensured this | |||||

| 7 | Quality Plans | ||||

| 7.1 | SLM 4.06.02 Issue 3 Clause 5.1 States… | SLM 4.06.02 - 5.1 | |||

| The contractor will agree the use of Quality Plans, Inspection and Test Plans and Method Statements with the customer at the Opening up Meeting. From this point on in this document these will be known as Quality Plan(s) however the requirements apply also to Inspection and Test Plans and Method Statements. Refer to SLSP 2.15.01.01 and associated forms. | |||||

| Review the minutes of the meeting and verify the requirements were met. | |||||

| 7.2 | SLM 4.06.02 Issue 3 Clause 5.2 States… | SLM 4.06.02 - 5.2 | |||

| The distribution for review and approval of Quality Plans and/or Inspection and Test Plans shall be agreed at the start up/kick off meeting for the Contract, Project, task specific purchase orders or operations. | |||||

| Verify this was recorded in the Opening up meeting minutes | |||||

| 7.3 | SLM 4.06.02 Issue 3 Clause 5.3 States… | SLM 4.06.02 - 5.3 | |||

| The Contractor shall ensure a Quality Plan and/or Inspection and Test Plans (or Quality Plans) is/are in place for the contracted scope of work. Where the work covers a number of phases for example design, manufacture, construction, installation and commissioning, separate quality plans shall be prepared, submitted and identified on a Sellafield Ltd Supply Chain Model SLF 1.10.315.13. | |||||

| Verify Quality Plans are in place, as required | |||||

| 7.4 | SLM 4.06.02 Issue 3 Clause 5.4 States… | SLM 4.06.02 - 5.4 | |||

| Dependent upon the size and complexity of the work scope it may be more appropriate to generate more than one quality plan. In these instances a top level Quality Plan should be prepared for the identified scope and reference each individual sub-Quality Plan and Inspection and Test Plan (where applicable). Benefits of this approach allow for quality plans to be produced concurrent with the phase of work and allow for closure when complete. | |||||

| Has an over-arching Quality Plan been necessary as above? Does it fulfil its purpose with references to all sub Quality Plans referenced? | |||||

| 7.5 | SLM 4.06.02 Issue 3 Clause 5.5 States… | SLM 4.06.02 - 5.5 | |||

| The Contractor shall submit the quality plan(s) and Inspection and Test Plans to the customer for acceptance within 10 working days of receipt of the contract. | |||||

| Was the deadline achieved? | |||||

| 7.6 | SLM 4.06.02 Issue 3 Clause 5.6 States… | SLM 4.06.02 - 5.6 | |||

| The Contractor shall not commence work identified in the quality plan and Inspection and Test Plans prior to confirmation of acceptance by the customer. | |||||

| Was work commenced prior to approval? | |||||

| 7.7 | SLM 4.06.02 Issue 3 Clause 5.7 States… | SLM 4.06.02 - 5.7 | |||

| The Contractor shall document in quality plans the controls to be applied to its Subcontractors. Any change to an approved/accepted quality or Inspection and Test Plans plan shall be resubmitted to the customer for approval and/or acceptance. | |||||

| Verify requirements are met | |||||

| 7.8 | SLM 4.06.02 Issue 3 Clause 5.8 States… | SLM 4.06.02 - 5.8 | |||

| Specialist processes within the specification shall be identified within the quality plan and Inspection and Test Plans. These will require approval by Sellafield Ltd. Typical special processes include but are not limited to welding, pipe work bending, heat treatment, non-destructive testing, material finishes and concrete mix design. | |||||

| Review Quality Plans for inclusion of special processes and the approval of these by SL before use. | |||||

| 7.9 | SLM 4.06.02 Issue 3 Clause 5.9 States… | SLM 4.06.02 - 5.9 | |||

| For products and services, the quality plan and /or Inspection and Test Plans shall conform to the following Sellafield Ltd criteria, | |||||

| Verify compliance for each sub clause below: | |||||

| 7.10 | SLM 4.06.02 Issue 3 Clause 5.9.1 States… | SLM 4.06.02 - 5.9.1 | |||

| The quality plan and /or Inspection and Test Plans shall be prepared listing the activities necessary to demonstrate compliance with the specified requirements and to discharge the work. The activities shall be listed in a logical sequence and be broken down into a level of detail required to discharge the work, for example, phases associated with the contract lifecycle and different packages of work. | |||||

| 7.11 | SLM 4.06.02 Issue 3 Clause 5.9.2 States… | SLM 4.06.02 - 5.9.2 | |||

| The quality plan and Inspection and/or Test Plans shall identify against activities all applicable procedures, controlling arrangements, accountability for delivery and associated records. The wording and output of the activity shall be clear, concise and unambiguous. | |||||

| 7.12 | SLM 4.06.02 Issue 3 Clause 5.9.3 States… | SLM 4.06.02 - 5.9.3 | |||

| The quality plan and Inspection and/or Test Plans shall identify the minimum records to be included in the lifetime records. These records shall be reviewed, approved and accepted in accordance with the specification and contract requirements. | |||||

| 7.13 | SLM 4.06.02 Issue 3 Clause 5.9.4 States… | SLM 4.06.02 - 5.9.4 | |||

| Sellafield Ltd reserves the right to identify hold points in the quality plan and /or Inspection and Test Plans. The Sellafield Ltd representative may identify hold points in the Quality Plan beyond which work must not proceed without Sellafield Ltd verification and/or permission. If work commences prior to Sellafield Ltd’s acceptance of the Quality Plan, or work progresses past a hold point without the required sign off on the Quality Plan, Sellafield Ltd shall raise a non conformance requiring corrective and preventive action. | |||||

| 7.14 | SLM 4.06.02 Issue 3 Clause 5.9.5 States… | SLM 4.06.02 - 5.9.5 | |||

| To monitor the work, the quality plan and Inspection and Test Plans shall facilitate the signing off of all activities against the agreed Inspection Activity Codes identified in the approved quality plan. | |||||

| 7.15 | SLM 4.06.02 Issue 3 Clause 5.9.6 States… | SLM 4.06.02 - 5.9.6 | |||

| The quality plan and Inspection and Test Plans shall consist of three main parts: cover sheet, documentation sheet and activity sheet. | |||||

| The cover sheet shall identify the following: | |||||

| · Company name | |||||

| · Title | |||||

| · Reference numbers (Sellafield Ltd contract number, contractor reference number and Subcontractor reference number if applicable) | |||||

| · Plant item number or material master number | |||||

| · Scope of work the quality plan covers | |||||

| · Activity codes and description | |||||

| · SQEPed nominated roles for signing off the quality plan activities | |||||

| · Quality plan acceptance – (names, signatures and dates) | |||||

| · Final sign off when the quality plan is complete | |||||

| 7.16 | SLM 4.06.02 Issue 3 Clause 5.9.7 States… | SLM 4.06.02 - 5.9.7 | |||

| The documentation sheet shall identify all standards and specifications applicable to the scope of work | |||||

| 7.17 | SLM 4.06.02 Issue 3 Clause 5.9.8 States… | SLM 4.06.02 - 5.9.8 | |||

| The activity sheets shall identify activities and activity codes, documents, nominated roles and records required to be generated to be included in the lifetime records. | |||||

| 8 | Assurance | ||||

| 8.1 | SLM 4.06.02 Issue 3 Clause 7.3 States… | SLM 4.06.02 - 7.3 | |||

| The contractor shall develop and implement a risk based assurance programme which aligns to the graded approach to procurement. The audit programme shall cover the scope of work to be undertaken by the Contractor during each financial year | |||||

| Confirm that the required audit programme is in place and being complied with. | |||||

| Review actions raised and the effectiveness of their close out. | |||||

| 8.2 | SLM 4.06.02 Issue 3 Clause 7.6 States… | SLM 4.06.02 - 7.6 | |||

| The Contractor shall report to Sellafield Ltd deficiencies identified from their assurance programme that will affect compliance with contractual requirements. Corrective actions shall identify remedial measures and preventive actions to avoid recurrence. | |||||

| If this was required, verify the effectiveness of the measures and actions | |||||

| 8.3 | SLM 4.06.02 Issue 3 Clause 7.8 States… | SLM 4.06.02 - 7.8 | |||

| The Contractor shall notify Sellafield Ltd of any Management Review actions which will affect compliance with contractual requirements. Management Review output shall identify responsible persons and due dates for completion of agreed action. | |||||

| Review the minutes from the last Management review meeting. Verify action taken and compliance with due dates | |||||

| 8.4 | SLM 4.06.02 Issue 3 Clause 7.9 States… | SLM 4.06.02 - 7.9 | |||

| The Contractor shall in accordance with the Contract requirements establish and agree a set of metrics to enable measurement of performance against contracted and subcontracted work scopes. The metrics shall as a minimum measure the Contractor’s safety, schedule, quality and cost performance. | |||||

| Review the metrics for compliance | |||||

| 8.5 | SLM 4.06.02 Issue 3 Clause 7.10 States… | SLM 4.06.02 - 7.10 | |||

| The Contractor shall report the agreed cumulative metrics to the Customer at each financial period end. The Contractor shall report subcontractor performance to Sellafield Ltd using Sellafield Ltd form SLF 1.10.315.14. | |||||

| Review reported metrics from Contractor and Subcontractors for last financial period end | |||||

| 8.6 | SLM 4.06.02 Issue 3 Clause 7.11 States… | SLM 4.06.02 - 7.11 | |||

| The Contractor shall cascade the metrics to its Subcontractors to measure their performance. Upon request, the metric data shall be shared with Sellafield Ltd for the purpose of measurement of supply chain performance. | |||||

| Verify compliance | |||||

| 8.7 | SLM 4.06.02 Issue 3 Clause 7.12 States… | SLM 4.06.02 - 7.12 | |||

| The Contractor shall ensure specific, measurable, achievable, realistic and time bound (SMART) action is taken if Subcontractor performance is not achieving the required standard or upon the identification of a deteriorating and/or adverse trends. | |||||

| Where sub contractor performance is not satisfactory, what actions were taken? | |||||

| 9 | Certificate of Conformity (C of C) | ||||

| 9.1 | SLM 4.06.02 Issue 3 Clause 11.11 States… | SLM 4.06.02 - 11.11 | |||

| Where required, the Contractor shall supply a document certified by a competent authority that the supplied good or service meets the required specifications. This is also referred to as a certificate of compliance or certificate of conformity. Details required to be identified on the Certificate of Conformance, as a minimum, are: | |||||

| Contract / Purchase Order Number (Unique identifier) | |||||

| Compliance to referenced Specification (BS EN 10204 certificate) | |||||

| Drawing Number (if appropriate) | |||||

| Item identification and number of items covered under C of C | |||||

| Verify that the C of C carries at least the minimum requirements and is the document certified by a “competent authority” Has the Contractor verified with the supplier that the signatory has been authorized and is SQEP? | |||||

| 10 | Records | ||||

| 10.1 | SLM 4.06.02 Issue 3 Clause 13.1 States… | SLM 4.06.02 - 13.1 | |||

| The Contractor shall ensure that all Lifetime Records including those generated by Subcontractors are compiled in accordance with SLP 2.15.05 and its subsets concurrently with the activity to which they relate. | |||||

| Verify that the records are being compiled in accordance with the above SLP and the agreed project records from the Initial project meeting with SL. | |||||

| 10.2 | SLM 4.06.02 Issue 3 Clause 13.3 States… | SLM 4.06.02 - 13.3 | |||

| Where radiography is required, the Contractor shall conform to ES_0_5260_2 General Procedure & Guidance specification for radiographic examination. | |||||

| Verify that the contractor is adhering to the ES specification quoted | |||||

| 10.3 | SLSP 2.15.05.01 Section 1.5 states… | SLSP 2.15.05.01 - 1.5 | |||

| The Contractor shall ensure that records are stored at a predetermined location(s) in containers and/or cabinets constructed and maintained to mitigate the risk of loss, damage, or destruction from: | |||||

| a natural disasters (fire, winds and flooding) | |||||

| b environmental conditions (high and low temperatures and humidity) | |||||

| c infestation of insects, mould, or rodents | |||||

| d dust or airborne particles | |||||

| e radiation/contamination | |||||

| LTR’s shall not be held in a production area to avoid the possibility that they could be damaged, destroyed, mislaid and to prevent deterioration. Only authorised personnel should be allowed access to the records. | |||||

| Verify storage conditions are met and that there exists an authorised personnel listing. | |||||

| 11 | Internal Audit and Programme | ||||

| 11.1 | ISO 9001: 2008 - 8.2.2 Internal audit states…. | ISO 9001: 2008 - 8.2.2 | |||

| “The organization shall conduct internal audits at planned intervals to determine whether the quality management system | |||||

| a) conforms to the planned arrangements (see 7.1), to the requirements of this International Standard and to the quality management system requirements established by the organization, and | |||||

| b) is effectively implemented and maintained. | |||||

| An audit programme shall be planned, taking into consideration the status and importance of the processes and areas to be audited, as well as the results of previous audits. The audit criteria, scope, frequency and methods shall be defined. The selection of auditors and conduct of audits shall ensure objectivity and impartiality of the audit process. Auditors shall not audit their own work. | |||||

| A documented procedure shall be established to define the responsibilities and requirements for planning and conducting audits, establishing records and reporting results. | |||||

| Records of the audits and their results shall be maintained (see 4.2.4) | |||||

| The management responsible for the area being audited shall ensure that any necessary corrections and corrective actions are taken without undue delay to eliminate detected nonconformities and their causes. | |||||

| Follow-up activities shall include the verification of the actions taken and the reporting of verification results (see 8.5.2). | |||||

| Review the internal audit schedule applicable to the contracted scope of work. | |||||

| 11.2 | Does the organisation have an Audit programme that focuses upon Product Quality related processes as follows: | Not Specified | |||

| · SQEP | |||||

| · Weld Procedures and Qualifications | |||||

| · NDT Procedures and Qualifications | |||||

| · Material Segregation and Workface cleanliness | |||||

| · Calibration | |||||

| · LTR compilation | |||||

| · Sub Contract Management | |||||

| · Quality Planning | |||||

| · Painting and Coating procedures | |||||

| · Testing Procedures | |||||

| Review NIS internal Audit programme to verify that te above points are included. | |||||

| 11.3 | SLM 4.06.02 Issue 3 Clause 7.3 States… | SLM 4.06.02 - 7.3 | |||

| The contractor shall develop and implement a risk based assurance programme which aligns to the graded approach to procurement. | |||||

| The audit programme shall cover the scope of work to be undertaken by the Contractor during each financial year | |||||

| Verify if the Audit Programme been generated in line with contract key milestones and risks | |||||

| 12 | Document Control | ||||

| 12.1 | BS EN ISO 9001:2008 Section 4.2.3 | ISO 9001: 2008 - 4.2.3 | |||

| Review the Control of Documents process for compliance to the following: | |||||

| Control of documents received by the organisation | |||||

| Document registration | |||||

| Document identification | |||||

| Control of issue, revision and amendments | |||||

| Document distribution | |||||

| Version/change control | |||||

| Control of obsolete documents | |||||

| Control of Sensitive documents | |||||

| Obtain evidence to verify compliance to the above | |||||

| 12.2 | SLP 2.15.05 section 1.1 States… | SLP 2.15.05 - 1.1 | |||

| The Sellafield project/demander/quality team shall review the scope of work and prepare | |||||

| Section 1 of SLF 2.15.05.01 and issue to the Contractor/Supplier (refer to para. 3.1 of the | |||||

| SLF Notes for Completion), at the tender stage as part of the works information pack. | |||||

| The requirement for the contractor to create a LTR Information Handover Strategy (as per | |||||

| Appendix 3 of SLSP 2.15.05.01 & SLSP 1.10.315.01) shall also be clearly communicated at this point. | |||||

| Does the organisation have standard LTR indexes in accordance with SLF 2.15.05.01? | |||||

| 12.3 | SLM 4.06.02 Issue 3 Clause 2.12 States… | SLM 4.06.02 - Clause 2.12 | |||

| The Contractor’s procedure for controlling documents between Subcontractors and the customer shall ensure documents are clearly identifiable to each Subcontractor. Version control of documents between the Contractor, Subcontractor and the customer shall be appropriately managed. | |||||

| Verify the above requirement | |||||

| 13 | Welding Arrangements | ||||

| 13.1 | ES_O_5394_2 section 6.1 Welding Responsibility states… | ES_O_5394_2 Section 6.1 | |||

| In conformance with BS EN ISO 3834-2, the Contractor shall appoint an individual to be responsible for co-ordinating all welding activities for Builds 1, 2, 3 and 4 (vessels and tanks). | |||||

| This individual maybe supported by other responsible welding personnel dependant upon the complexity of fabrication. The responsibilities of the welding co-ordinator shall encompass those welding activities as detailed in the clauses laid out in BS EN ISO 3834-2, as appropriate to the contract. | |||||

| The welding co-ordinator shall demonstrate to the satisfaction of the client his/her knowledge and experience on welding co-ordination activities. This can be possession of a nationally recognised welding inspection qualification or having the minimum qualifications and/or experience to satisfy the requirements of the European Welding Federation. All welding shall be carried out in accordance with the requirements of BS EN 1011 Parts 1, 2, 3, 6 & 7. All welding to be carried out to written procedures approved by the Client | |||||

| Obtain evidence that …….. have a weld co-ordinator that satisfies the above requirements | |||||

| 13.2 | SMF _SPEC_0003 Issue C Section 5.1 Inspection and Testing General states in part… | ||||

| General butt and fillet welds shall comply with the levels of acceptance called for in BS EN ISO 5817, level B. | |||||

| Fillet welds subject to stress in structurally important members shall comply with the acceptance levels of BS EN ISO 5817, Table 1, Quality level B. | |||||

| Obtain objective evidence to demonstrate compliance to the above. | |||||

| 13.3 | ES_0_5394_2 Issue 2 Clause 6.2 Welding Supervision States… | ES_O_5394_2 section 6.2 | |||

| The Contractor shall ensure that there is regular and systematic supervision and inspection of all welding work. When welding operations are taking place a Contractors Inspector or Inspector shall be available to carry out in process welding inspections at any time during welding operations. | |||||

| Obtain objective evidence to demonstrate compliance to the above. | |||||

| 13.4 | ES_0_5394_2 Issue 2 Clause 6.3 Welding Equipment states… Welding plant and equipment (manual or automatic) shall be regularly serviced, maintained and calibrated using the measured output for the given power source setting and fixed arc length, in conjunction with an instrument of known calibration. All instrumentation used for or to monitor the welding process shall be fully calibrated. Records of calibration and periodic checks of equipment shall be retained and made available to the Inspector. All work, filler and gas circuits shall be free from moisture during welding. The contractor shall ensure that electrical cables are not damaged or in a state of disrepair. An inspection and maintenance program shall be in place to ensure the condition of welding cables is such that no harm or damage could be caused by their use. Cables shall be inspected upon release from / return to store. Where cables are on site for extended periods of time, the inspection and maintenance program shall ensure these cables are checked on a regular basis. Where cables are likely to come into contact with other services or plant items, the contractor shall ensure that cables are suitably insulated or mechanically suspended. Review welding equipment for compliance to the above requirements. ES_O_5394_2 section 6.3 ES_O_5391_2 Section 7.4 Acceptance and testing of welders States… |

ES_O_5394_2 Section 6.3 | |||

| Welding plant and equipment (manual or automatic) shall be regularly serviced, maintained and calibrated using the measured output for the given power source setting and fixed arc length, in conjunction with an instrument of known calibration. All instrumentation used for or to monitor the welding process shall be fully calibrated. Records of calibration and periodic checks of equipment shall be retained and made available to the Inspector. All work, filler and gas circuits shall be free from moisture during welding. The contractor shall ensure that electrical cables are not damaged or in a state of disrepair. An inspection and maintenance program shall be in place to ensure the condition of welding cables is such that no harm or damage could be caused by their use. Cables shall be inspected upon release from / return to store. Where cables are on site for extended periods of time, the inspection and maintenance program shall ensure these cables are checked on a regular basis. Where cables are likely to come into contact with other services or plant items, the contractor shall ensure that cables are suitably insulated or mechanically suspended |

|||||

| Review welding equipment for compliance to the above requirements. | |||||

| 13.5 | ES_0_5394_2 Issue 2 Clause 6.5 Welding Procedures States… | ES_O_5394_2 section 6.5 | |||

| All welding operations shall be carried out to written procedures this includes repair welds. | |||||

| Repair procedures and initial welding procedures shall be offered for approval by the clients SME prior to contract commencement. These procedures shall include all the basic information from the initial joint preparation to final weld inspection. | |||||

| Approval of weld procedures shall be subject to satisfactory completion of procedure approval tests in accordance with BS EN ISO 15607, BS EN ISO 15609-1 and BS EN ISO 15614-1. | |||||

| Review applicable welding procedures including repair to confirm compliance. | |||||

| 13.6 | ES_0_5394_2 Issue 2 Clause 6.8 Consumables States… | ES_O_5394_2 section 6.8 | |||

| Unless otherwise stated in the contract documents or drawings, filler material shall conform to the requirements of Table 1. If the consumable is not stated then advice should be sought from the clients SME. | |||||

| The Contractor shall operate a formal system for the verification of electrodes, filler rods, wire and submerged arc flux/wire combinations prior to release for manufacture. | |||||

| Certificates of test covering each batch and/or cast number of such weld consumables (in conformance with BS EN 10204 type 3.1) shall be supplied to the Inspector for approval before work is commenced. Packaged materials shall be marked conspicuously with the batch and/or cast number as appropriate. | |||||

| The Contractor shall operate a formal system for the verification of electrodes, filler rods, wire and submerged arc flux/wire combinations prior to release for manufacture. | |||||

| It is the client’s expectation that companies carrying out TIG or Plasma welding shall use non Thoriated tungsten electrodes. Where Thoriated tungsten electrodes are employed for TIG or plasma welding, contractors shall ensure that appropriate measures exist with respect to storage, handling and disposal of any grinding residues (see HSE doc 564/61). | |||||

| Review consumable process for compliance | |||||

| 13.7 | ES_0_5394_2 Issue 2 Clause 6.8.2 Issue of Filler Materials | ES_O_5394_2 section 6.8.2 | |||

| The Contractor shall satisfy the Inspector that a documented system is operated which identifies materials correctly and includes relevant issue details. Only one batch of electrodes/filler material per size shall be issued to a welder. | |||||

| Unused filler materials shall be returned to store at the end of the day or shift where they can be checked and re-identified. Filler materials, which cannot be identified, shall be discarded. | |||||

| Review consumable process for compliance | |||||

| 14 | NDT Arrangements | ||||

| 14.1 | ES_O_5394_2 Issue 2 Clause 3.2 NDE Schedule States… The NDE Schedule shall define:- |

ES_O_5394_2 Section 3.2 | |||

| All proposed NDE methods, procedures and acceptance criteria which shall be applied to all welds on a fabrication. | |||||

| Explaining the proposed method of a NDE process applied to a weld or similar welds and any short comings of the proposed NDE method and also any other NDE process which can supplement the original NDE process. | |||||

| Each NDE method shall have an approved NDE procedure which shall be authorised by a PCN Level 3 in the NDE method and approved by the clients own PCN Level 3 for that method | |||||

| All NDE operators’ qualifications and experience shall be assessed for their suitability to carry out NDE to the schedule. | |||||

| This process shall be agreed between the contractor(s) and client prior to fabrication commencing. | |||||

| The NDE Schedule shall be a Hold Point in the relevant Quality Plan or Inspection and Test Plan which ever is applicable. | |||||

| Review the NDE schedule to the requirements stated above | |||||

| 14.2 | ES_O_5394_2 Issue 2 Clause 7.1 Weld Inspection states… | ES_O_5394_2 Section 7.1 | |||

| Testing shall be carried out in the order shown by this clause, where necessary. | |||||

| 2. Liquid Penetrant/Magnetic Particle Inspection | |||||

| The contractor shall ensure the fabrication sequence is planned in such a manner to ensure all of the mandatory inspections can be completed. This includes giving access to complete all inspections, as indicated above, before access is denied when moving onto the next weld or joint. Failure to comply will result in rejection and rework will be necessary by reinstalling satisfactory access. | |||||

| Review the weld inspection process for compliance for the LPI/MPI process | |||||

| Obtain evidence that the NDE procedures have been approved by SL | |||||

| 14.3 | ES_O_5394_2 Issue 2 Clause 7.3 Weld Inspection states… | ES_O_5394_2 Issue 2 Clause 7.3 | |||

| Completed welds shall be subject to visual and surface crack detection examination as detailed NISow. This shall be carried out in accordance with documented procedures, approved by the Client, be consistent with the requirements of BS EN ISO 17637 and BS EN ISO 3452-1 or BS EN ISO 17638 as appropriate. The extent of weld examination shall be as follows: | |||||

| a) 100 % visual of all stainless steel and carbon steel welds. b) 100% LPI of all stainless steel welds. c) 100% MPI of all direct load path and structural welds in carbon steel. |

|||||

| Lifting points shall be examined before and after proof load testing (if applicable). If doubts exist as to the integrity of visually examined welds, then the Inspector reserves the right to request surface crack detection at the Contractors expense. For repetitive items in stainless steel, which do not contain load bearing or structural welds, it maybe appropriate to agree to a percentage sampling for surface crack detection. Such consideration shall be given provided the following criteria are satisfied: |

|||||

| a) Items are fabricated from the same grade of material. b) Items are fabricated at the same contractor’s works and completed during the same day or shift. c) Items are fabricated using the same process, welding procedure and welder (certified to BS EN 287-1) |

|||||

| Obtain evidence that the organisation have the appropriate amount of qualified inspection and NDT operatives to deliver against the SL specification requirements and the scope of work? (Verify currency and prolongation) | |||||

| Obtain evidence of NDT personnel qualifications that are maintained. (tie in with resource section) Obtain evidence that NDE testing equipment sampled is calibrated and in date |

|||||

| 15 | Testing Arrangements (Pressure, Leak and Load Testing) | ||||

| 15.1 | SMF_SPEC_0003 Issue C Section 5.7 Proof load testing states in part… | SMF_SPEC_0003 Issue C Section 5.7 | |||

| All tests shall be carried out before any surface preparation/painting has taken place. NDE of welded joints may be required after completing the testing and this shall be identified in the Quality Plan/Inspection test Plan. Proof load testing shall be carried out by a competent person using a test load of 125% the safe working load (SWL). The full test load shall be applied for a duration of not less than 2 minutes. Proof load testing shall be witnessed by the contractors inspector or by a third party inspection authority nominated by the customer. |

|||||

| Obtain evidence that the Testing Procedures been submitted and approved by SL. Identify through evidence the qualified testing operatives to deliver against SL work. Verify the storage and calibration arrangements for testing equipment. (Tie in with Calibration section). |

|||||

| 15.2 | SMF_SPEC_0003 Issue C Section 5.8 Leak testing states in part… | SMF_SPEC_0003 Issue C Section 5.8 | |||

| Leak testing shall be carried out before any surface preparation/painting has taken place. Enclosed box sections and cavities shall be subject to a leak test only where the equipment specific manufacturing drawing identifies this as a requirement. Leak testing shall consist of applying filtered compressed air at low pressure (150mm) water gauge max) to box sections/cavities that have been covered externally with a 2% solution of ‘Synperonic A7’ or equivalent in water for a minimum period of 10 minutes. The surface shall be examined for leaks which, if detected shall be corrected at source. After satisfactory completion of the test the section shall be dried out and seal weld applied to the air inlet. |

|||||

| Identify through objective evidence any leak testing carried out in accordance to the above. | |||||

| 15.3 | 45046_JFN_MECH_SP_B874_131_0010 Section 7.4 EC&I Inspection & Testing Requirements states… | JFN_MECH_SP _B874_131_0010 Section 7.4 |

|||

| Testing and inspections shall include as a minimum the following: | |||||

| • Check for conformity to specification including drawings, documentation and standards. • Visually examine for standard of workmanship and finish • Check dimensions against drawings including fixings • Check that wiring and circuits are correctly made, identified and that polarity has been observed (point to point checks) • Check connections and joints including testing of crimped connection by ‘pull testing’ • Check the information on labelling of the equipment e.g. fuses and terminal banks and any warning labels • All circuit breaker/fuse/overload rating shall be checked and circuit breaker/fuse holders shall be shall be marked with the rating and service. The circuit breaker /fuses and isolating switches shall be checked to ensure that they are connected to the correct circuits. Check that power distribution and circuit protection is such that equipment can be removed safely without affecting equipment on any other loop • Check against requirements of BS EN 60204-1 [Ref 20] • All power carrying terminals to conform to IP2X • All installation to be suitably earth bonded in line with applicable standards |

|||||

| Review the planned testing arrangements regarding EC&I, review ITP in line with the above requirements. | |||||

| 16 | Painting and Coating Arrangements (Optional) - | ||||

| 16.1 | ES_O_5394_2 section 10 Painting States… | ES_O_5394_2 section 10 | |||

| Where required, in accordance with specification ES_1_5142_3 or contract documents or associated drawings. | |||||

| Review if any painting specifications are applicable and approved by SL | |||||

| 16.2 | ES_O_5394_2 section 10 Galvanising States… | ES_O_5394_2 section 10 | Not applicable | ||

| ES_O_5394_2 section 10 Galvanising States… Where required, in accordance with the specification listed in the contract documents or associated drawings. Galvanised fabrications shall be inspected in accordance with the specification listed in the contract documents or associated drawings for galvanising defects. Galvanised fabrications may require trial assembly to ensure that adequate clearances are maintained and items will fit together |

|||||

| Review if any galvanising specifications are applicable and approved. Who is qualified within the organisation for coating? Obtain evidence. Is Painting and Coating subcontracted out? If so demonstrate Flow down of SL requirements. |

|||||

| 17 | Foreign Material Exclusion process | ||||

| 17.1 | SLM 4.06.02 Issue 3 Clause 11.24 Foreign Material Exclusion states… | SLM 4.06.02 - Clause 11.24 | |||

| The Contractor shall have a Foreign Materials exclusion process. The process shall include but is not limited to the following: | |||||

| · Identification as to whether Foreign Materials exclusion principles apply to the scope of work and if so, when, i.e. final vessel closures, works testing, dismantling, packing and dispatch. | |||||

| · Identification, segregation and management of Foreign Materials exclusion areas. | |||||

| Identification and use of materials, equipment, processes and systems demonstrating their status, i.e. 5S, shadow boards, lanyards, work management, materials control including items to be removed or added such as bolts, washers, items in or items out, and management of waste arising such as swarf. | |||||

| Verify if a FME process is established to the above requirements. | |||||

| Document what training/awareness has been given to personnel within the organisation regarding FME | |||||

| 18 | Counterfeit, Fraudulent and Suspect Items (CFSI) | ||||

| 18.1 | SLM 4.06.02 Issue 3 Clause 11.3 states… | SLM 4.06.02 - Clause 11.3 | |||

| The Contractor shall ensure that processes are in place to mitigate the risk of Suspect and Counterfeit products being deployed to Sellafield Ltd. The processes shall include identification of Suspect and Counterfeit products, assurance of product source, selection of suppliers and verification that purchased products meet the specified requirements. | |||||

| What has the contractor in place to meet this requirement? | |||||

| Has the contractor made their supply chain aware of the issues surrounding CFSI and its possible effects on Nuclear Safety? | |||||

| What coaching and training has the organisation given to their workforce regarding CFSI? | |||||

| 18.2 | SLM 4.06.02 Issue 3 Clause 11.4 states… | SLM 4.06.02 - Clause 11.4 | |||

| In the event of suspect or counterfeit products being found the Contractor shall immediately notify the Customer in case a similar item is in use, and initiate the Non Conformity process. | |||||

| Is there an instruction or similar in place detailing the actions of its staff on discovery of CFSI? | |||||

| 18.3 | SLM 4.06.02 Issue 3 Clause 11.5 states… | SLM 4.06.02 - Clause 11.5 | |||

| The Contractor shall ensure that processes are in place to control and document the disposition of products identified as Suspect. Sellafield Ltd shall be provided records of the dispositions of Suspect products, as agreed at the opening up meeting. | |||||

| Verify the processes in place and determine their effectiveness. | |||||

| 19 | Calibration Arrangements | ||||

| 19.1 | SLM 4.06.02 Issue 3 Clause 9.1 states… | SLM 4.06.02 - Clause 9.1 | |||

| The Contractor shall maintain a register of measurement and test equipment. | |||||

| Review register for completeness, how is recall for recalibration effected and is it being complied with? | |||||

| 19.2 | SLM 4.06.02 Issue 3 Clause 9.2 states… | SLM 4.06.02 - Clause 9.2 | |||

| The Contractor shall maintain measurement and test equipment, calibrated and traceable to International or national standards for the duration of the contract | |||||

| Verify sample calibration records, test house used is accredited or certified to calibrate the item in question with the required traceability of master equipment used. | |||||

| 19.3 | SLM 4.06.02 Issue 3 Clause 9.3 states… | SLM 4.06.02 - Clause 9.3 | |||

| The Contractor shall notify the customer of any product that may be affected by the failure of Measurement and Test Equipment or by the Measurement and Test Equipment failing recalibration. The Contractor shall evaluate the impact on product affected by such equipment; this product shall be treated as nonconforming product until demonstrated otherwise | |||||

| Verify that the Contractors records allow traceability to where each piece of equipment has been used, should the failure occur. | |||||

| 20 | CE Marking for Structural Steelwork (Optional) | ||||

| 20.1 | Has the organisation been awarded certification against BS EN IS0 1090 | ISO 1090 | |||

| Obtain detail of Certification | |||||

| 20.2 | Are all the required control arrangements implemented on the shop floor? | ISO1090 | |||

| Supplier to demonstrate this | |||||

| 20.3 | Are Execution Class requirements identified for the scope of work? | ISO1090 | |||

| Confirm these requirements | |||||

| 20.4 | Are controlling arrangements aligned to the latest SL Specification (G11)? | ISO1090 | |||

| Verify the organisation has a knowledge of G11 | |||||

| 20.5 | Does the organisation generate and issue a Declaration of Performance and individual certificates for each batch of Steel? | ISO 1090 | |||

| Verify through objective evidence | |||||

| 21 | Non-Conformance | ||||

| 21.1 | SLM 4.06.02 Issue 3 Clause 8.1 states… | SLM 4.06.02 - Clause 8.1 | |||

| The Contractor shall establish a documented process to identify record, clarify and resolve technical problems with respect to Sellafield Ltd and/or customer requirements prior to or during the implementation of the contracted work scope. | |||||

| Review the process in use for effectiveness and traceability. | |||||

| 21.2 | SLM 4.06.02 Issue 3 Clause 8.2 states… | SLM 4.06.02 - Clause 8.2 | |||

| The Contractor shall establish a documented process to identify, clarify, resolve and close out non-conformances throughout the life of the contract. | |||||

| Review process for effectiveness. | |||||

| Note: Non Conformances raised during Internal audits will be captured in the Internal; audit section. | |||||

| 21.3 | SLM 4.06.02 Issue 3 Clause 8.3 states… | SLM 4.06.02 - Clause 8.3 | |||

| The Contractor shall establish a documented process to identify a request for deviations or a justification for the use of non - conforming product from Sellafield Ltd specified requirements, aligned with: | |||||

| · SLP 1.02.18 How do I resolve engineering queries, | |||||

| · SLP 2.15.04 How Do I Monitor and Report Non Conformances? | |||||

| · SLF 1.03.124 Defect/Non- conformance Report | |||||

| For direct Sellafield Ltd contracts completed requests should be submitted to the Customer representative as agreed at the opening up meeting. All the documents shall be marked with the Sellafield Ltd contract number and project number (if applicable). | |||||

| Review process for effectiveness | |||||

| 21.4 | SLM 4.06.02 Issue 3 Clause 8.4 states… | SLM 4.06.02 - Clause 8.4 | |||

| Upon identification of nonconforming product or service the Contractor shall ensure the product is clearly identified, segregated, controlled, recorded, and reported to the appropriate level of management within the organisation and then reported onwards to their customer. | |||||

| Review process and verify compliance | |||||

| 21.5 | SLM 4.06.02 Issue 3 Clause 8.6 states… | SLM 4.06.02 - Clause 8.6 | |||

| The Contractor and its Subcontractors shall not repair work or correct spoilt work after (final) inspection by the nominated inspectorate without the prior written approval from Sellafield Ltd. | |||||

| Has this occurred? | |||||

| 22 | Traceability | ||||

| 22.1 | ES_0_5394_2 section 4.14. Transfer of identification States… | ES_0_5394_2 section 4.1 | |||

| Transfer of identification is not required, other than for:- • The provision of material certificates. • To ensure material type and cast, batch numbers are not lost due to cutting of material. The contractor shall maintain a system whereby all material in the completed work shall be easily traced to its origin and the construction drawings and shall be recorded in any weld records. |

|||||

| Verify the above process. | |||||

| 22.2 | ES _5394_2 Section 4.2.1 Acceptance of Materials States… | ES_0_5394_2 section 4.2.1 | |||

| The storage and handling of welding consumables shall be in accordance with BS EN 1011 Part 1. For guidance on the approval of materials in contact with stainless steel refer to ES_0_5363_1 Review the consumable process for compliance |

|||||

| Verify the transfer of identity process. | |||||

| 22.3 | ES _5394_2 6.8 Consumables States… | ES_0_5394_2 section 6.8 | |||

| Unless otherwise stated in the contract documents or drawings, filler material shall conform to the requirements of Table 1. If the consumable is not stated then advice should be sought from the clients SME. The Contractor shall operate a formal system for the verification of electrodes, filler rods, wire and submerged arc flux/wire combinations prior to release for manufacture. Certificates of test covering each batch and/or cast number of such weld consumables (in conformance with BS EN 10204 type 3.1) shall be supplied to the Inspector for approval before work is commenced. Packaged materials shall be marked conspicuously with the batch and/or cast number as appropriate. It is the client’s expectation that companies carrying out TIG or Plasma welding shall use non Thoriated tungsten electrodes. Where Thoriated tungsten electrodes are employed for TIG or plasma welding, contractors shall ensure that appropriate measures exist with respect to storage, handling and disposal of any grinding residues (see HSE doc 564/61). |

|||||

| Unless otherwise stated in the contract documents or drawings, filler material shall conform to the requirements of Table 1. If the consumable is not stated then advice should be sought from the clients SME. The Contractor shall operate a formal system for the verification of electrodes, filler rods, wire and submerged arc flux/wire combinations prior to release for manufacture. Certificates of test covering each batch and/or cast number of such weld consumables (in conformance with BS EN 10204 type 3.1) shall be supplied to the Inspector for approval before work is commenced. Packaged materials shall be marked conspicuously with the batch and/or cast number as appropriate. It is the client’s expectation that companies carrying out TIG or Plasma welding shall use non Thoriated tungsten electrodes. Where Thoriated tungsten electrodes are employed for TIG or plasma welding, contractors shall ensure that appropriate measures exist with respect to storage, handling and disposal of any grinding residues (see HSE doc 564/61) |

|||||

| Review the consumable process for compliance to the above requirements | |||||

| 23 | Goods Inward Inspection | ||||

| 23.1 | SLM 4.06.02 Issue 3 Clause 11.16 States… | SLM 4.06.02 - Clause 11.16 | |||

| The Contractor shall establish a process for goods inward inspection. The process shall ensure the following: | |||||

| Plant and materials are received with a copy of the relevant 5059 (Final Certificate of Inspection) or equivalent certificate, | |||||

| Plant and materials shall be accompanied by a manufacturer’s Delivery note and should be checked for quantities and transport damage. | |||||

| Plant, materials and associated certification are be booked into an approved storage or lay down area and allocated with a unique identification number. | |||||

| Plant and materials that are found to be damaged or considered to be outside of specified requirements are immediately quarantined | |||||

| Can the process be verified as effective? | |||||

| 23.2 | ES_0_5360_2 Section 5.1 States… | ES_0_5360_2 Section 5.1 | |||

| All Incoming stainless steel materials and components shall be kept segregated from other materials and components and only allocated to stores and fabrication areas following formal clearance and completion of all necessary documentation. | |||||

| 5.2 Quarantined or non-conforming material shall be segregated from other stock and identified accordingly | |||||

| Review the goods receipt process meets the requirements of the section 5.1 and 5.2 and verify the following; | |||||

| Stores personnel understand the procedure | |||||

| Store-man can demonstrate identification of materials | |||||

| Store-man understands material segregation | |||||

| Is able to demonstrate the quarantine process. | |||||

| Is suitably trained. | |||||

| Does Supplier stock rotate items with specific shelf life | |||||

| 23.3 | SLM 4.06.02 Issue 3 Clause 11.6 States… | SLM 4.06.02 - Clause 11.6 | |||

| The Contractor shall supply to Sellafield Ltd Original Material Mill Certificates listing the mechanical and chemical properties as required by the contract specification. Where this is not possible copies shall be taken and endorsed by authorised Personnel in red ink as “verified true certified copies of the original”. | |||||

| Review NIS process for Material Certification requirements for compliance. | |||||

| 23.4 | SLM 4.06.02 Issue 3 Clause 11.7 States… | SLM 4.06.02 - Clause 11.7 | |||

| Where a product has been manufactured from a previously certified material the Contractor shall provide endorsed certificates of both material products produced by one manufacturer and reworked by another manufacturer, for example fittings made from pipe or plate, flanges made from a forging or plate. | |||||

| Verify if NIS can provide evidence of both endorsed certificates. | |||||

| 23.5 | SLM 4.06.02 Issue 3 Clause 11.8 States… | SLM 4.06.02 - Clause 11.8 | |||

| The Contractor shall review and endorse the Original Material Mill Certificates or certified copies to verify conformance with the contract specification prior to the commencement of work. | |||||

| NIS review the Mill Certification prior to material release, confirm compliance through objective evidence. | |||||

| 24 | Goods Release Process | ||||

| 24.1 | ES_0_5360_2 section 9 Storage of Materials States… | ES_0_5360_2 section 9 | |||

| The storage and handling of welding consumables shall be carried out in accordance with BS EN 1011 Part 1 ES_0_5360_2 Section 9 Issue of material Section 9.1 States…Confirmation of identity/quality shall be established on all materials prior to issue. If identity cannot be satisfactorily established the material shall not be accepted. 9.2 Materials should be retained and issued with their cast number and/or batch number identity as appropriate. |

|||||

| ES_0_5360_2 Section 9 Issue of material | |||||

| Section 9.1 States…Confirmation of identity/quality shall be established on all materials prior to issue. If identity cannot be satisfactorily established the material shall not be accepted. | |||||

| Section 9.2 Materials should be retained and issued with their cast number and/or batch number identity as appropriate. | |||||

| Review the NIS process for compliance to SL specifications of goods release. | |||||

| Who is responsible for carrying out goods release and can the organisation provide evidence of training? | |||||

| How is goods release recorded? | |||||

| Is there a designated goods release area within the facility? | |||||

| 24.2 | ES_O_5394_2 section 16 Marking And Despatch States… | ES_0_5394_2 Section16 | |||

| Unless instructions to the contrary are given in the contract documents or relevant drawings, fabrications shall have the following markings:- |

|||||

| (a) The Contract Number. (b) Plant item number. (c) Weight - if applicable to contract (d) CE (European Conformity) - if applicable to contract |

|||||

| The method of marking shall be as stated in the contract documents. Except where the contract documents specify hard stamping, markings shall be painted on in 25mm high black characters (for large fabrications 75mm high characters may be used). For stainless steel, halogen free adhesive labels (2 off minimum, using 20mm printed characters) may be substituted. For guidance on approval, see ES_0_5363_1 |

|||||

| Confirm the Marking of item is compliant to A-D | |||||

| 24.3 | SLM 4.06.02 Issue 3 Clause 11.17 States… | SLM 4.06.02 Issue 3 11.17 |

|||

| The Contractor shall not dispatch product identified as requiring an interim release note until authorisation has been obtained from Sellafield Ltd by the issue of a signed Sellafield Ltd form SLF 2.15.02.04 – “Intermediate Certificate of Inspection (Form 5199)”. |

|||||

| Obtain objective evidence of the use of the 5199 and the NIS process involved | |||||

| 24.4 | SLM 4.06.02 Issue 3 Clause 11.18 States… | SLM 4.06.02 - 11.18 |

|||

| The Contractor shall not dispatch to Sellafield Ltd any product unless authorisation has been obtained from Sellafield Ltd by the issue of a signed Sellafield Ltd Form SLF 2.15.02.05 – “Final Certificate of Inspection (Form 5059)”. | |||||

| Obtain objective evidence of the use of the 5059 and the NIS process involved. | |||||

| 25 | Packaging and Transport | ||||

| 25.1 | ES_0_5360_2 The Storage and Handling of Stainless Steel Materials, Components and Fabrications Packing and transport States… | ES_0_5360_2 | |||

| Appropriate precautions shall be taken at all times during loading, transit and unloading to avoid mechanical damage and to prevent any ingress of rain, spray, dust or any contaminants such as those specified ES_0_5363_1. | |||||

| Obtain objective evidence of the following; | |||||

| Applicable packing procedure/s | |||||

| Awareness of contactable materials | |||||

| Proper use of tapes and laNISs | |||||

| Robustness of protection during transport. | |||||

| Evidence of training | |||||

| Checking of packing prior to despatch | |||||

| Inspection and Test Plans See Quality Plans | |||||

| 26 | Fabrication drawings (Design) | ||||

| 26.1 | SLM 4.06.02 Issue 3 Clause 10.5 States … | SLM 4.06.02 - 10.5 |

|||

| When the design responsibility lies with the Contractor as defined within the contract, the Contractor shall identify and implement their proposed design reviews on a quality plan that has to be accepted by the Customer prior to the commencement of work. | |||||

| Can this be verified for the lifting beams and accessories as required by the vessel spec section 3.4. | |||||

| Review if drawings are available on the shop floor. | |||||

| Are they current revision and how are they controlled | |||||

| 26.2 | SLM 4.06.02 Issue 3 Clause 10.10 States … | SLM 4.06.02 10.10 | |||

| The Contractor shall document the results of all design reviews and transmit the results to the customer. Actions resulting from design reviews shall be completed before final customer approval of the design. | |||||

| Can this be verified? | |||||

| 26.3 | SLM 4.06.02 Issue 3 Clause 10.12 States… | SLM 4.06.02 - 10.12 |

|||

| Review, checking and approval of design outputs shall be undertaken by suitably qualified and experienced Personnel independent of those having direct responsibility for the work being performed. | |||||

| Review the qualifications and authorised level of checking of the persons named | |||||

| 27 | Facilities | ||||

| 27.1 | ES_0_5360_2 Section 11.1 States… | ES_0_5360_2 - 11.1 - 11.3 | |||

| Manufacturing and fabrication facilities shall be dry and indoors and provided with suitable inspection facilities including calibrated equipment. | |||||

| ES_0_5360_2 Section 11.2 States… | |||||

| The manufacturing and fabrication facilities shall be segregated and kept free of all possible contaminating materials, such as lead, zinc, copper/copper alloys or carbon steels etc. – see ES_0_5363_1 for further guidance. | |||||

| ES_0_5360_2 Section 11.3 States… | |||||

| The stainless steel used for manufacture or fabrication shall be adequately protected during all stages of fabrication/manufacture from possible contamination. | |||||

| Review Supplier facilities for compliance to the SL specification requirements in relation to cleanliness and tidiness. | |||||

| Are the facilities secure? | |||||

| Has Supplier the capability to meet the contract requirements? | |||||

| 0 | |||||||||||||||||||||||||||||||

| 0 | |||||||||||||||||||||||||||||||

| 0 | |||||||||||||||||||||||||||||||

| 0 | |||||||||||||||||||||||||||||||

| 0 | |||||||||||||||||||||||||||||||

| 0 | 0 | ||||||||||||||||||||||||||||||

| 0 | 0 | ||||||||||||||||||||||||||||||

| 0 | 0 | ||||||||||||||||||||||||||||||

| 0 | 0 | 0 | |||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||

| Nuclear Safety Culture | Quality Management System | Resource Management | Procurement | Subcontractor Selection & Control | Contract Review | Quality Plans | Assurance | C of C | Records | Internal Audit & Programme | Document Control | Welding Arrangements | NDT Arrangements | Testing Arrangements | Painting & Coating | FME | CFSI | Calibration | CE Marking | Non Conformance | Traceability | Goods Inward | Goods Release | Packaging & Transport | Fabrication Drawings | Facilities | |||||

| Target | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||

| Findings | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | Finding | #DIV/0! | |

| Verified | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | Verified | #DIV/0! | |

| RFT | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | #DIV/0! | |||

| Standards | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | ISO 9001:2008 | ES _0_5391_2 | ES _0_5391_2 | ES _0_5391_2 | ES _0_5391_2 | SLM 4.06.02 | SLM 4.06.02 | SLM 4.06.02 | ISO 1090 | SLM 4.06.02 | ES_0_5391_2 | ES_0_5360_2 & SLM 4.06.02 | ES_0_5360_2 & ES_0_5391_2 | ES_0_5360_2 | SLM 4.06.02 | ES_0_5360_2 | ||||

| Supplier Assist Development Tracker | ||||||||

| SL Subject Matter Expert : | ||||||||

| Point of Contact : | ||||||||

| No: | Findings | Supplier Response | Actionee (Supplier) | Approved By (SL) | Expected Completion Date | Progress Notes | Verification | Date Completed |

no reviews yet

Please Login to review.