135x Filetype PDF File size 1.02 MB Source: www.bca.gov.sg

10. COMMON DEFECTS AND REMEDIES

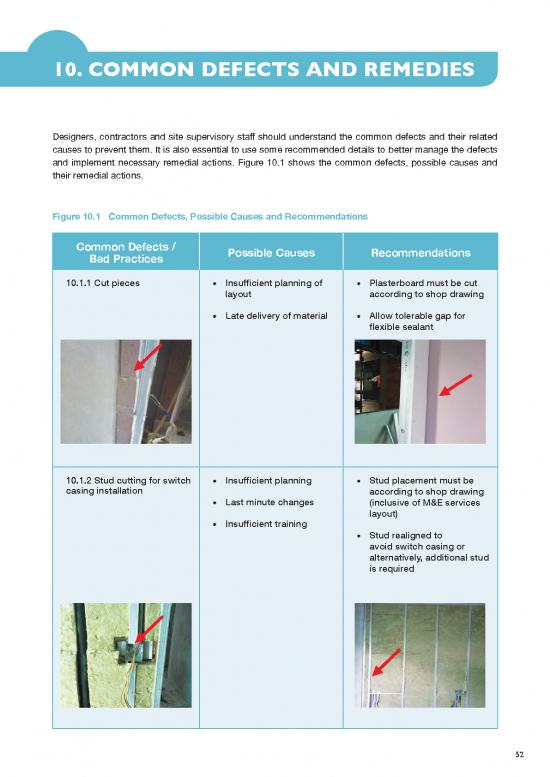

Designers, contractors and site supervisory staff should understand the common defects and their related

causes to prevent them. It is also essential to use some recommended details to better manage the defects

and implement necessary remedial actions. Figure 10.1 shows the common defects, possible causes and

their remedial actions.

Figure 10.1 Common Defects, Possible Causes and Recommendations

Common Defects / Possible Causes Recommendations

Bad Practices

10.1.1 Cut pieces • Insufficient planning of • Plasterboard must be cut

layout according to shop drawing

• Late delivery of material • Allow tolerable gap for

flexible sealant

10.1.2 Stud cutting for switch • Insufficient planning • Stud placement must be

casing installation according to shop drawing

• Last minute changes (inclusive of M&E services

• Insufficient training layout)

• Stud realigned to

avoid switch casing or

alternatively, additional stud

is required

52

COMMON DEFECTS AND REMEDIES

Common Defects / Possible Causes Recommendations

Bad Practices

10.1.3 Poor cutting of • No provision of right tools • Panel must be cut according

plasterboard to shop drawing

• Insufficient training • Over cut / slanting / Rough

cut is not allowed

10.1.4 Missing timber stiffener • Insufficient planning • Timber (1x2 or 2x2) as

• Insufficient training stiffener

• Alternatively, it has to be

double studs to form boxed

at door jamb

10.1.5 Gaps between different • Insufficient planning • All gaps are to be sealed

materials using Fire Rated Sealant or

• No gap allowed • Insufficient training relevant sealant

• Gap was filled by mortar • Lack of supervision

filling instead of flexible

sealant.

53

COMMON DEFECTS AND REMEDIES

Common Defects / Possible Causes Recommendations

Bad Practices

10.1.6 Gaps between • Insufficient training • Joints must be tightly butt

plasterboard tapered end board edge

• Joints not tightly butt • Poor workmanship joints

tapered end board edge

joints

10.1.7 Studs not fastened to • Lack of supervision • All Studs and Bracing must

bottom track be riveted/ screwed

• Insufficient training

• Poor workmanship

54

COMMON DEFECTS AND REMEDIES

Common Defects / Possible Causes Recommendations

Bad Practices

10.1.8 M&E Services not • Insufficient planning • All Electrical Services must

within drywall setting out be within drywall setting out

• Insufficient training

• Poor workmanship

10.1.9 Small cut pieces • Insufficient planning • Full piece & proper joint.

installed and torn board

• Insufficient training

• Poor workmanship and

supervision

10.1.10 Bottom track cut to • Insufficient planning • Services Holes was created

accommodate M&E services without cutting track

• Insufficient training

• Poor workmanship and

supervision

55

no reviews yet

Please Login to review.