218x Filetype PDF File size 0.07 MB Source: www.irbnet.de

Specifications For Road Construction And

Maintenance With Warranty Contracts

Q Li A Kumar & S De Silva

Civil & Geological Engineering, RMIT University, Melbourne, Australia

Summary: Several road agencies around the world are exploring the use of warranty type contracts

in road construction and maintenance. International practices show that the specifications used in

warranty type contracts are significantly different to the conventional approaches. In this paper,

some key issues in developing specifications for warranty contracting are identified. The issues

addressed include criteria for product selection, duration of the warranty, performance indicators

and thresholds, quality control/quality assurance, remedial actions, conflict resolution team,

warranty bond and payment, etc

Keywords. Warranty, specifications, road construction, maintenance

1 INTRODUCTION

Budgetary constraints and increased public awareness of road conditions have encouraged road agencies to examine alternative

road construction contracting methods. In the last decade, various innovative contracting processes, such as design-build, A+B

Biding, lane rental, warranty and job order contracting have been implemented in road construction industry (UTTC 2000).

International practices indicate that warranty contracts can reduce on-going maintenance costs, encourage contractors’

innovation, and eventually benefit road users (Kumar 2001, Russell et al 1999). This paper is intended to address some key

issues in developing specifications for warranty road construction and maintenance.

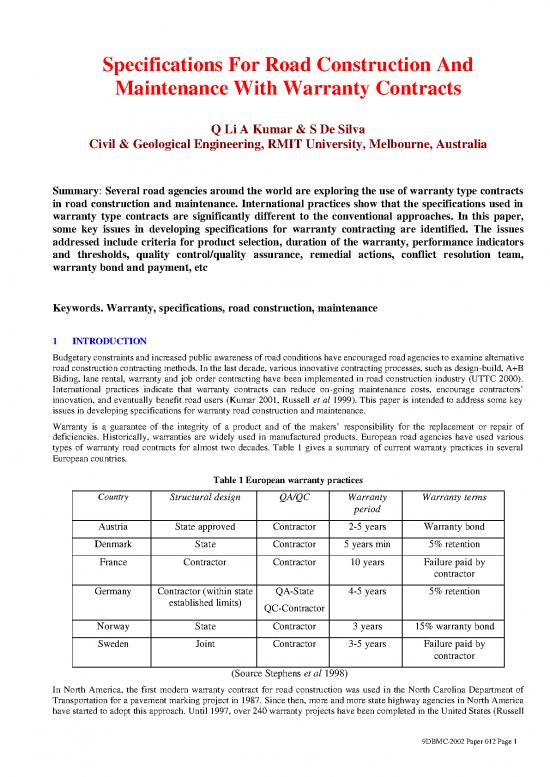

Warranty is a guarantee of the integrity of a product and of the makers’ responsibility for the replacement or repair of

deficiencies. Historically, warranties are widely used in manufactured products. European road agencies have used various

types of warranty road contracts for almost two decades. Table 1 gives a summary of current warranty practices in several

European countries.

Table 1 European warranty practices

Country Structural design QA/QC Warranty Warranty terms

period

Austria State approved Contractor 2-5 years Warranty bond

Denmark State Contractor 5 years min 5% retention

France Contractor Contractor 10 years Failure paid by

contractor

Germany Contractor (within state QA-State 4-5 years 5% retention

established limits) QC-Contractor

Norway State Contractor 3 years 15% warranty bond

Sweden Joint Contractor 3-5 years Failure paid by

contractor

(Source Stephens et al 1998)

In North America, the first modern warranty contract for road construction was used in the North Carolina Department of

Transportation for a pavement marking project in 1987. Since then, more and more state highway agencies in North America

have started to adopt this approach. Until 1997, over 240 warranty projects have been completed in the United States (Russell

9DBMC-2002 Paper 012 Page 1

et al 1999). In Australia and New Zealand, several state road agencies have started to adopt the process on a trial basis in

recent years.

2 TYPES OF SPECIFICATIONS IN ROAD CONSTRUCTION AND MAINTENANCE

2.1 Method and material-based specifications

Traditionally, method and material-based specifications have been used by highway agencies to control construction and

maintenance quality. In theory, these specifications reduce job delays and contract claims, and contract compliance is easily

determined. However, there are two major disadvantages. Firstly, it gives no opportunity and motivation for contractors to

improve the construction processes or the final constructed product. Secondly, full-time presence of experienced personnel

from contracting agencies is required for proper enforcement.

2.2 Quality control/quality assurance specifications

Quality control/quality assurance was developed to primarily improve the method and material-based processes. As used in

industrial manufacturing, the specifications, based on representative sampling and statistical acceptance procedure, outline

contractors’ strategies and procedures for controlling quality. Contractors are allowed to use preferred means and method to

provide the end result to meet the statistical acceptance requirements of the owners. To some extent, it can take advantages of

the contractors’ experience and innovation. The constraint of quality control/quality assurance specifications is that the

specifications are absolute acceptance and rejection. In reality, there is a gray area in which the product is below the

acceptance criteria but still provides value to the owners. This largely depends upon the type of product.

2.3 Performance–related specifications

Performance–related specifications were developed to provide an improvement over quality control/quality assurance

specifications. Performance–related specifications describe the desired levels of fundamental engineering properties that are

predictors of performance and appear in primary performance relationships. The specifications intend to quantify and link the

properties of the materials and construction process to the performance of the end product. However, researchers (Ohrn &

Schexnayder 1998) have acknowledged that the primary relationships involved in developing performance–related

specifications were more complicated than anticipated. More work is required in establishing performance prediction models

that can realistically quantify the effects of the variation of material properties and construction quality on the performance of

the end product.

2.4 Warranty specifications

Under an ideal warranty contract, the specification is expressed directly in terms of desired performance parameters and

thresholds at various times throughout the warranty period. The contractors are given the freedom of materials selection and

construction methods. Under current practices, warranty specifications are generally written as a combination of quality

control/quality assurance specification and performance-related specification (Russell et al 2000). The details are addressed in

the following sections.

2.5 End result specifications

Transportation Research Board (TRB) described the end result specifications as “specifications that required the contractor to

take the entire responsibility for supplying a product or an item of construction. The highway agency’s responsibility is to

either accept or reject the final product or apply a price adjustment that compensates for the degree of compliance with the

specifications” (Benson 1995). Generally, the specifications can be found in Design-Build-Operation, Design-Build-Operation-

Transfer contracting approaches.

The distinctive difference between end result specification and performance–related specification is that the former focuses on

the measurements of the end product and the latter measures the indicators of material properties and quality during the

construction process. Under an end result specification, the contractor takes fully responsibility in deciding what to do and

how.

3 POTENTIAL BENEFITS AND CONSTRAINTS OF USING “WARRANTY” IN ROAD CONSTRUCTION AND

MAINTENANCE

3.1 Potential benefits

When using warranty specifications, the final product is assessed in terms of performance parameters directly related to the

road users. Therefore, contractors are expected to provide a safe and usable roadway for public rather than to simply meet

prescriptive standards on construction materials and methods.

In comparing with traditional contracting processes, warranty contracting relocates some post-construction performance risks

between the contractor and contracting agency. Therefore, a higher accountability for construction quality is passed on to the

contractor. Contractors are in a better position to manage the day-to-day quality due to their direct relationship with suppliers

9DBMC-2002 Paper 012 Page 2

and subcontractors and their direct control over construction activities. They have more interest in adopting a new construction

method if it offers possible competitive advantage. Theoretically, a higher quality is more likely to be achieved by using

warranty contracting.

Under this process, contractors have to a large extent, the freedom to select materials and construction methods. Therefore the

agency is no longer simply purchasing the contractor’s labor, equipment, and material, but is also ultilising contractor’s

experience and innovation. The process stimulates contractors to improve their construction techniques in order to maximise

profits. Any cost savings arisen from such innovation will also be passed on to the agency and the community.

International practices shows that warranty contracting decreases the demands on owner’s human and physical resources

(Russell et al 2000, Stephens et al 1998). Due to contractors taking responsibility of quality control/quality assurance, there are

less demands on daily in-field inspection during construction period. In post-construction stage, the situation is also improved

because contractor has to repair and correct possible deficiencies during the warranty period.

3.2 Problems and constraints

Current warranty specifications are the combination of quality control/quality assurance specification and performance–related

specifications. Although extensive work has been done to predict performance behavior of pavements, the relationships are

still being tested and verified.

Theoretically, the length of warranty period is generally determined by the “time to identify the deficiencies of the end

products”. However, in some cases, the determination of the duration of the contract is based on the discussion between the

contracting community and the owner. The warranty periods vary from 2 to 20 years. As agencies gain more experience, the

duration may be changed.

Experiences in other industry sectors, such as the pipeline industry, indicate that even though warranty specifications are

detailed, installation in some cases may not occur to these specifications. Therefore, the construction supervisors may still play

an important role in quality assurance in critical works such as gas industry.

Compared to traditional approaches, warranty processes prolong the contracting duration that does increase contracting

administration tasks for both agencies and contractors. Most agencies ask for bonds or retain parts of the bid amount for the

warranty works. Small contractors may be eliminated from the market due to financial incapability for warranty projects. Even

for large companies, ongoing increased outstanding warranty obligations may result in difficulties to get bond for new projects.

In general, warranty approach is new for the road construction industry. With the increase of warranty type contracts, its long-

term impact on cost savings and performance of end product will be better identified.

4 KEY ISSUES IN DEVELOPING WARRANTY SPECIFICATIONS FOR ROADWORKS

Previous research (Russell et al 1999) has proposed a framework with eleven key elements for warranty specifications.

However, some important issues in developing a warranty specification should be further investigated.

4.1 Product selection criteria

In current practices, the warranty products for road construction and maintenance include asphalt pavement, chip seal, micro-

surfacing, concrete pavement, bridge components, bridge painting, pavement marking, etc. Generally, the product for warranty

should have the following attributes (UTTC 2000):

a) Performance of the product is measurable and quantifiable. The failure thresholds can be well defined in the

specification.

b) The warranty work is wholly controlled by the contractor, and allows the contractor to select optimal design,

construction process and material.

c) The factors beyond contractor’s control have minimal impact on the warranty product, or the possible defects associated

can be well identified.

4.2 Duration of warranty

The warranty periods vary from 2 to 20 years. It is generally accepted that five years is an acceptable evolution period to assure

the performance of an asphalt product, without overburdening the contractors. Typical warranty periods for chip seal and micro

surfacing are about 3 and 2 years, respectively. In some cases, the warranty period is determined by dialogue between agency

and contracting community. However, care should be taken whether the agreed period is appropriate for deficiency

identification. A comprehensive reviewing of past maintenance records is essential before finalising the agreement.

4.3 Warranty bond and payment

Most agencies ask for bond or retain some percentage of contract amount for remedial work guarantee. In Indiana, USA, a

bond is required. The amount is based on the cost to remove and replace the warranty asphalt work. Michigan, USA, keeps

9DBMC-2002 Paper 012 Page 3

10% of the contract lump sum price of the contract item as the bond. Similar to Michigan, partial contract price is withheld in

Ohio, however, the percentage is varied based on the course thickness (as given in Table 2).

Table 2 Percent of retainment versus course thickness in Ohio

Course thickness Percentage

2.0 inches (50mm) or less 90%

2.1 to 4.0 inches (51 to 100mm) 60%

4.1 inches (101mm) or more 30%

(Source ODOT 1999 b)

Table 3 Michigan warranty payments versus year

Period Year Payment as % of Contract LSUM

1 0

2 1

3 2

4 3

5 4

(Source MDOT 1995)

According to a survey conducted by Stephen et al. (1998), the bond issue is one of the major concerns in contracting

community. Small and medium size contractors believed that they would face financial difficulties with accumulative bond

requirements. The bond agents also expressed concern on their long-term financial conditions from prolonged project duration.

It suggests that an ongoing dialogue on bond issue between highway agencies and contracting community will be critical for

successful implementation of warranty approach.

Warranty payment can be made annually. Normally, the payment is made based upon an annual inspection of the pavement

made by the agency to determine its condition relative to the warranty performance criteria. In Michigan, the performance

payments are made within 30 days after the anniversary date of the acceptance of the pavement construction. The percentage

of payment for each year is given in Table 3.

4.4 Conflict resolution team

Study undertaken by Russell et al (1999) found that half of the state agencies in North America had a conflict resolution team

in warranty projects. The scope of the team includes all issues related to material selection, quality control plan, distress rate,

and remedial works. This team is especially useful for partial reconstruction, chip seal (spray seal), and micro-surfacing

projects. In these projects, the contractor has to accept pre-existing conditions that may result in the damage of the warranty

products.

Indiana (USA) conflict resolution team consists of two contractor representatives, two department representatives, and a fifth

person mutually agreed upon by both parties. In case of dispute, the team will give a final recommendation by a majority vote

in which each member has an equal vote. The cost for the fifth member will be equally shared between the agency and the

contractor.

4.5 Performance indicators and thresholds

The selection of performance parameters is important in developing a warranty specification (Kumar 2001). For road users,

ride quality and safety are two major concerns. The agency, in addition, expects that the products contribute to low life-cycle

cost. Performance indicators should include the above expectations. The performance indicators generally fall into three

categories: safety, ride quality, and quality performance.

Skid resistance is generally accepted as an appropriate safety measure for pavement running surface. Standard methods such as

the friction number test, have been used world wide.

One widely used measure of ride quality is Present Serviceability Index (PSI). The drawback of this approach is that it is based

on subjective opinion of the evaluation panel. With the promotion of the World Bank models, there is a growing interest in the

highway industry for using International Roughness Index (IRI). This objective measure can be acquired by standard

equipment at highway travel speed.

9DBMC-2002 Paper 012 Page 4

no reviews yet

Please Login to review.